Barley

Please check back later for additional changes

Barley is a member of the grass family and is considered a cereal grain. Malted barley is a raw material used for the production of beer because of its high starch content with low gelatinization temperature, as well as natural enzymes (see Malt and Mashing). However unmalted barley can also be used as an adjunct. Different varieties of barley exist, and they have different characteristics. Be aware that in professional literature "barley" may refer to unmalted barley, whereas malted barley is simply called "malt".

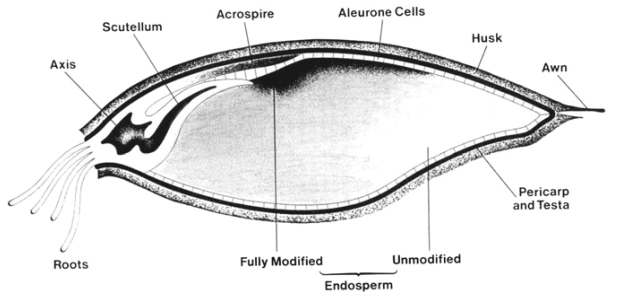

The three main tissues of the barley seed are the aleurone layer, embryo, and starchy endosperm that account for about 9, 4, and 87%, respectively, of the seed dry weight.[1]

Barley grain is composed by embryo, endosperm and husk, with each of them having different functions (Holopainen-Mantila, 2015). Embryo is the most important living tissue initiating grain germination when absorbs water. Endosperm is the dead storage organ mainly comprising of starch, protein, and non-starch polysaccharides. Within the endosperm, starch granules are embedded in the protein matrix (Brennan, Harris, Smith, & Shewry, 1996; Chmelík et al., 2001; Fox, 2009). During germination, endogenous starch hydrolytic enzymes are produced and/or activated in the aleurone and scutellum cell layers and migrate into the endosperm, causing partially hydrolysis/modification of starch granules. In general, whole barley grain consists of 51–77% starch, 10–17% protein, 4–9% β-glucan, 2–3% free lipids and 1.5–2.5% minerals (Gupta, Abu-Ghannam, & Gallaghar, 2010).[2]

Barley has a high level of beta-amylase and is one of the few cereals that retains a husk after threshing. Barley became the standard grain for beer production in most regions of the world as it could be grown or easily obtained.[3]

The endosperm is the storage compartment with the major components being starch and protein and lesser components (by amount) including cell wall components, phenolic acids and lipids. The endosperm is constructed with cells crammed with starch, proteins, and lipids while the cell walls are composed of mainly of β-glucan (70 %) and arabinoxylan (20 %).[3]

The number of starch granules in a cell and amount of starch are more influenced by growing environment than by genetics.[3]

Although barley does not have the highest level of starch compared with other brewers grains (Table 16.1), the starch is negatively correlated to protein content (Fox et al., 2011). In addition, barley is ideally suited as it retains a physical skin or hull after the seed is harvested (Fox et al., 2006a). This hull has an important role to play in the brewing process as it provides a filter bed during mashing (see Section 3.9.1).[4]

Use of two-row is most prevalent.[5] Two-row barleys (compared to six-row) produce large, plump grains, usually with thinner, finely wrinkled husks. Consequently they contain larger amounts of starch with less husk, and therefore also fewer tannins and bitter substances. Two-row also has less beta-glucans and protein, which is favorable.[6][5] Spring barley (grown from March to September) is generally better for brewing due to its selective cultivation over the centuries, while winter barley is mainly used as feed.[7]

From a brewers’ view-point, six-row barley may be less desirable compared to a two-row owing to non-uniformity of the seed size of the former. Furthermore, six-row barley tend to have more protein content and hence less starch than the latter.[8]

Although modern winter barleys are of equivalent quality to spring barleys, there is a perception in some quarters that winter barleys are of poorer quality. This is clearly not the case. For example, Maris Otter is a winter barley, and its celebrated malting quality is equivalent to or better than the best spring barleys.[9]

Starch, at 54-65% dry weight, is the main constituent of barley.[10]

Barley malt starch: 60-67% for base malts, as low as 7% for special malts.[11]

The protein content of barley is normally between 10-11.5%. Only a fraction of these proteins pass into the finished beer. Most is removed with the spent grains or trub.[7] The most abundant amino acids are glutamine, leucine, arginine, phenylalanine, and valine.

Soft barley grain is related to higher malt friability which is positively related to higher extract and fermentable. Thus, soft barley is the better quality and grain hardness is easily measured.[3]

The husk constitutes about 10-13% of the dry weight, and consistency mainly of cellulose, hemicelluloses (see Carbohydrates), lignan, and a small quantity of protein. Arabinoxylans in particular constitute a major component of the outer layers of the endosperm and husk.[12] The endosperm cell walls consist of roughly 80% beta-glucans and 20% arabinoxylans.

Barley mainly contains the following vitamins:[7]

- Thiamine

- Riboflavin

- Ascorbic acid (small amounts)

- Tocopherol

Evaluating barley: See Kunze section 1.1.5.

Cell walls are central to the growth and development of the endosperm of cereal grains and to the remobilization of the stored reserves during germination. The endosperm consists of two distinct tissues, the aleurone and the starchy endosperm, that have different functions during grain development, dormancy and after germination. Cells of the starchy endosperm of barley and other cereals are non-living. They are packed with starch and storage protein reserves that are used to support the growth of the developing seedling following grain germination. Walls of the starchy endosperm are usually relatively thin compared with those of other organs and tissues, presumably because of the need for rapid removal of the walls during reserve mobilization after germination, and because the walls of the starchy endosperm do not have a major structural role in the grain , which is supported largely by the surrounding pericarp and seedcoat tissues.[13]

In contrast to cells of the starchy endosperm, the thick-walled, nucleated, aleurone cells are living at grain maturity, and are packed with protein bodies and lipid droplets. The reserve proteins, carbohydrates, lipids and other storage components of aleurone cells, together with hydrolytic enzymes and mitochondria, enable the rapid proliferation of the intracellular membrane system and the protein synthesising machinery, and provide amino adds for the synthesis of the hydrolytic enzymes that mediate starchy endosperm mobilization following germination. The walls of the aleurone layer consist of an inner, relatively thin layer and a thicker layer, but again have a relatively low cellulose content.[13]

The walls from barley endosperm are composed mainly of non-starchy polysaccharides, together with smaller amounts of protein and phenolic acids. The non-starchy polysaccharides of barley grains include cellulose, (1,3;1,4)-B-D-glucans, heteroxylans, which are mainly in the form of arabinoxylans, glucomannans, xyloglucans, pectic polysaccharides, callose, fructans, and arabinogalactan-proteins.[13]

Six-row generally contains more enzymes and non-enzymic proteins, and less starch (Mahalingam, 2017), and is commonly grown in North America.[14]

Two-row barley is usually preferred by both large-scale and traditional breweries, especially because it yields malts with greater extracts, lighter color, and lower protein content than six-row type. In contrast, six-row cultivars possess a higher diastatic power (a measure of the potential starch-converting enzymatic activity) and requires shorter steeping time for malting. To balance the effect of a higher protein content, malt from six-row varieties is usually cut with variable percentages of unmalted corn or rice grains.[15]

The main components of barley grain are starch (62.7%), proteins (11.1%), lipids (2.1%), fibre components (9.7%), moisture (12.1%) and minerals (2.3%).[16] The husk completely encases the grain separating living tissue from the outside environment. It protects the grain from physical damage and acts as a barrier to the diffusion of gases, water and solutes. The endosperm is the main tissue of the grain and is composed mostly of starch granules (1.7–2.5 µm to larger 22.5–47.5 µm granules) that are embedded in a protein matrix [1,4].

A recent study showed that both genetic differences between barley and the growing climate conditions can alter beer sensory descriptors, which the researchers concluded was most likely related to the malting performance of the barley.[16] (cites Yano, M.; Morikawa, M.; Yasui, T.; Ogawa, Y.; Ohkochi, M. Influence of wort oiling and wort clarification conditions on cardboard flavor in beer. Master Brew. Assoc. Am. Tech. Q. 2004, 41, 317–320.)

The outermost tissues of the kernel are collectively known as the hull or husk. These tissues thresh free from wheat, rye, and hull-less barley but are retained in standard malting barleys.[17]

The aleurone layer represents up to 10% of the weight of the barley kernel (85), surrounds most of the starchy endosperm, and is generally three cell layers thick. McNeil et al. (89) reported that barley aleurone cell walls are composed of 85% arabinoxylans and 8% cellulose. However, Bacic and Stone (8) later showed that the aleurone cell walls contain β-glucans (26%) in addition to arabinoxylans (67%) and cellulose (2%). They suggested that the larger amount of arabinoxylans reported by McNeil et al. (89) may have been due to the presence of endoglucanase in an α-amylase preparation used in the cell wall preparation.[17]

The starchy endosperm constitutes the majority (approximately 70%) of the kernel by weight, and the degradation of the cell walls is very important in both physiological and technological terms since they obstruct water and enzyme movement (85).[17]

Unmalted barley yields about 20% less extract than malt.[7][18] Starch granules from unmalted barley are broken down at slower rate than those from malt because they are very resistant to enzymes. Consequently, substantial amounts starch granules do not convert, and are discarded with the spent grains.[19]

Barley adjunct adds significantly more beta-glucans than malt, and thus increases wort viscosity, which may lead to lautering or filtering difficulty, or possibly even haze or gel precipitation.[10]

Unmalted barley tends to give beer a stronger harsher character, particularly stouts, and may cause lautering problems.[20] Barley adjunct improves foam stability, and reduces beer color.

Barley has normally been partially gelatinized prior to use, often in a location outside a brewery.[20]

Hulless barley has higher phenolic content and β-glucan compared to hulled varieties.[21] [22]

The use of barley instead of malt in the brewing process is interesting with respect to costs. However, in cost calculations it is important to consider that barley has a considerable enzyme deficit and requires the addition of microbially produced enzymes during the brewing process. Owing to the improving knowledge about brewing with barley using microbial enzyme cocktails during recent years, it is possible to brew beverages with a barley content of up to 100% without technological process problems in the brewery. However, there are different opinions with respect to the influence of unmalted barley on beer quality and flavour (1–14). Previous investigations showed a decrease in the colour, bitterness and free amino nitrogen (FAN) content and poor results in sensory analyses.[23]

Beneficially, barley proportions up to 50% (to a maximum of 75%) in the grist can be used to inhibit radical generation during the brewing process or beer storage and improve the oxidative wort and beer stability.[23]

Barley variety has a marked influence on the beer flavor stability, but treatments in the industrial malting plant may have much higher influence than do varietal factors.[24]

Potential sources

- "Influence of malt source on beer chemistry, flavor, and flavor stability"

- "Relationships among barley, malt, and beer phenolics"

- "Barley for brewing: Characteristic changes during malting, brewing and applications of its by‐products"

- "Influence of barley genetics on beer chemistry, flavor, and flavor stability"

- LOX-Less Barley

- http://www.themodernbrewhouse.com/wp-content/uploads/2017/04/BrewingScience_kunz_0811.pdf Improvement of the Oxidative Wort and Beer Stability by Increased Unmalted Barley Proportion

- http://www.themodernbrewhouse.com/wp-content/uploads/2017/04/Hoki_37-45.pdf Breeding of Lipoxygenase-1-less Malting Barley Variety CDC PolarStar and Effect of Lipoxygenase-1-less Trait on Beer Quality at Pilot and Commercial Scale Brewing

- https://pubs.acs.org/doi/pdf/10.1021/jf304932v

- Gupta Barley for Brewing: Characteristic Changes during Malting, Brewing and Applications of its By-Products

- https://www.homebrewtalk.com/threads/is-a-protein-rest-needed-for-6-row.699951/

- https://ambainc.org/news.php?Search=&Type=Resource&Tag=

See also[edit]

References[edit]

- ↑ Steiner E, Gastl M, Becker T. Protein changes during malting and brewing with focus on haze and foam formation: a review. Eur Food Res Technol. 2011;232:191–204.

- ↑ Yu W, Zhai H, Xia G, et al. Starch fine molecular structures as a significant controller of the malting, mashing, and fermentation performance during beer production. Trends Food Sci Technol. 2020;105:296–307.

- ↑ a b c d Bamforth CW, Fox GP. Critical aspects of starch in brewing. BrewingScience. 2020;73:126–139.

- ↑ Fox GP. Starch in brewing applications. In: Sjöö M, Nilsson L, eds. Starch in Food. 2nd ed. Woodhead Publishing; 2017:633–659.

- ↑ a b Howe S. Raw materials. In: Smart C, ed. The Craft Brewing Handbook. Woodhead Publishing; 2019.

- ↑ Fix G. Principles of Brewing Science. 2nd ed. Brewers Publications; 1999.

- ↑ a b c d Kunze W. Hendel O, ed. Technology Brewing & Malting. 6th ed. VLB Berlin; 2019.

- ↑ Mahalingam R. Shotgun proteomics of the barley seed proteome. BMC Genomics. 2017;18(44).

- ↑ Palmer GH. Barley and malt. In: Stewart GG, Russell I, Anstruther A, eds. Handbook of Brewing. 3rd ed. CRC Press; 2017.

- ↑ a b Krottenthaler M, Back W, Zarnkow M. Wort production. In: Esslinger HM, ed. Handbook of Brewing: Processes, Technology, Markets. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.

- ↑ Shopska V, Denkova-Kostova R, Dzhivoderova-Zarcheva M, Teneva D, Denev P, Kostov G. Comparative study on phenolic content and antioxidant activity of different malt types. Antioxidants. 2021;10(7):1124.

- ↑ Meussdoerffer F, Zarnkow M. Starchy raw materials. In: Esslinger HM, ed. Handbook of Brewing: Processes, Technology, Markets. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.

- ↑ a b c Burton RA, Collins HM, Fincher GB. The role of endosperm cell walls in barley malting quality. In: Zhang G, Li C, eds. Genetics and Improvement of Barley Malt Quality. Springer; 2010:190–237.

- ↑ Kerr ED, Fox GP, Schulz BL. Grass to glass: Better beer through proteomics. In: Cifuentes A, ed. Comprehensive Foodomics. Elsevier; 2020:407–416.

- ↑ Picariello G, Mamone G, Nitride C, Ferranti P. Proteomic analysis of beer. In: Colgrave ML, ed. Proteomics in Food Science. Academic Press; 2017:383–403.

- ↑ a b Gordon R, Power A, Chapman J, Chandra S, Cozzolino D. A review on the source of lipids and their interactions during beer fermentation that affect beer quality. Fermentation. 2018;4(4):89.

- ↑ a b c Egi A, Speers RA, Schwarz PB. Arabinoxylans and their behavior during malting and brewing. Tech Q Master Brew Assoc Am. 2004;41(3):248–267.

- ↑ Pahl R, Meyer B, Biurrun R. Wort and Wort Quality Parameters. In: Bamforth CW, ed. Brewing Materials and Processes: A Practical Approach to Beer Excellence. Academic Press; 2016.

- ↑ Bathgate GN, Palmer GH. In vivo and in vitro degradation on barley and malt starch granules. J Inst Brew. 1973;79(5):402–406.

- ↑ a b Stewart GG. Adjuncts. In: Stewart GG, Russell I, Anstruther A, eds. Handbook of Brewing. 3rd ed. CRC Press; 2017.

- ↑ Šimić G, Horvat D, Dvojković K, et al. Evaluation of total phenolic content and antioxidant activity of malting and hulless barley grain and malt extracts. Czech J Food Sci. 2017;35(1):73–78.

- ↑ Dvořáková M, Douanier M, Jurková M, Kellner V, Dostálek P. Comparison of antioxidant activity of barley (Hordeum vulgare L.) and malt extracts with the content of free phenolic compounds measured by high performance liquid chromatography coupled with CoulArray detector. J Inst Brew. 2008;114(2):150–159.

- ↑ a b Kunz T, Müller C, Mato‐Gonzales D, Methner FJ. The influence of unmalted barley on the oxidative stability of wort and beer. J Inst Brew. 2012;118(1):32–39.

- ↑ Guido LF, Curto AF, Boivin P, Benismail N, Gonçalves CR, Barros AA. Correlation of malt quality parameters and beer flavor stability: multivariate analysis. J Agric Food Chem. 2007;55(3):728–733.