Enzymes

Please check back later for additional changes

An enzyme is a protein that catalyzes a chemical reaction, greatly speeding it up while not being consumed by the reaction. This allows enzymes to be active even in very low concentrations. Enzymes play an important role in the creation of all fermented beverages, and more generally, they are needed for all life processes.[1] As with all proteins, enzymes have particular temperature and pH ranges in which they function, and more narrow ranges in which the activity is considered optimal.[2] The effect of temperature is greater than the effect of pH. Knowing the optimal ranges can be helpful, but it must be realized that the enzymes will be active to some extent outside those ranges.[3] Enzymes denature (the three-dimensional structure unfolds) at higher temperatures, rendering them inactive.[1] Enzymes tend to have a very specific substrate upon which they act, and therefore are often named after the substrate, adding "-ase" to the end.[4]

Coenzymes: The action of many enzymes is tied to the presence of an additional non-protein component that binds with its structure. For example, bivalent metal ions (e.g. iron, magnesium, calcium) are often involved as coenzymes.[5]

Isoenzymes: Enzymes that have different structures but catalyze the same reaction are called isoenzymes. Each isoenzyme may have different characteristics such as optimal temperature and pH ranges. Generally, most enzymes in living organisms have several isoenzymes.

Natural enzymes[edit]

Malting[edit]

Coming eventually

Enzymes are of special importance during malting. In post-harvest maturity, harvested malting barley contains a huge amount of enzymes and their precursors. From the malting point of view, enzymes of the hydrolasis group can be classified as the most important enzymes. They can be divided into four groups (cytolytic enzymes, proteolytic enzymes, phosphatases, amylases) and the class of oxidoreductases, followed then by transferases, lyases, isomerases, and ligases.[6]

- Cytolytic enzymes

Mashing[edit]

During mashing, a very large number of enzymes act simultaneously on the components of the grist under conditions that are far from optimal for many of them in terms of substrate concentration and accessibility, pH, and enzyme stability. Enzymes are progressively inactivated at different rates depending on the temperature, the pH, the presence of substrate and other substances (such as tannins and cofactors such as calcium ions) in solution.[3] Starch, proteins, nucleic acids, lipids and other substances are degraded, usually by hydrolytic (cleaving) reactions, but other reactions, such as oxidations, also occur.[7]

- Starch and sugar degradation (see Starch and Sugars)

- α-amylase (optimal 72–75°C, pH 5.6–5.8) degrades starch and dextrins into smaller sugars by cleaving α-1,4-bonds.[8][9][1][3] Rapid inactivation occurs at 78–80°C and above.[10][9]

- β-amylase (optimal 60–65°C, pH 5.4–5.6) releases maltose from the ends of sugar chains by cleaving α-1,4-bonds.[8][9][1] Rapid inactivation occurs at temperatures of 65-70°C and above.[10][9][11]

- Limit dextrinase AKA debranching enzyme AKA R-enzyme AKA pullulanase (optimal 55–65°C, pH 5.4) degrades limit dextrins into dextrins/sugars by cleaving the branch point (α-1,6 bonds).[8][9][12] Inactivation occurs at temperatures of 65-75°C and above, although it's not destroyed unless boiled.[10][9][11]

- α-glucosidase AKA maltase (optimum 35–45°C, pH 4.6–6.0) degrades maltose, isomaltose, oligosaccharides, dextrins and starch, cleaving single glucose units from the ends of chains (mainly α-1,4 bonds, but also some α-1,6 bonds).[3][8][13][14][15] This class of enzyme has not been studied to the same extent as the other starch-degrading enzymes.[16]

- Glucoamylase (optimal 35–40°C) cleaves a single glucose unit from the end of any sugar chain (both α-1,4 and α-1,6 bonds).[17][13] Its activity is virtually non-existent during mashing because of its very low optimal temperature.

- Invertase (optimal 50°C, pH 5.5) splits sucrose into glucose and fructose. Active up to 62–67°C.[9]

- Protein degradation and oxidation (see Protein)

- Endopeptidases, which include metalloproteases, cysteine proteases, aspartic proteases, and serine proteases (optimal 45–50°C, pH 3.9–5.5) over 40 different endopeptidase enzymes degrade proteins into peptides and free amino acids.[8][1]

- Carboxypeptidases (optimal 50°C, pH 4.8–5.6) degrade proteins & peptides into free amino acids.[8][1]

- Aminopeptidases (optimal 45°C, pH 7.0–7.2) degrade proteins & peptides into free amino acids.[8][1] Inactive during mashing.

- Dipeptidase (optimal 45°C, pH 8.8) degrades dipeptides into free amino acids.[8][1] Inactive during mashing.

- Thiol oxidase (optimal pH 8.0) catalyzes oxidation of thiols. Very active during mashing.[18]

- Beta-glucan liberation and degradation (see Beta-glucans and arabinoxylans)

- β-glucan solubilase (optimal 62–65°C, pH 6.8) releases high-molecular-weight matrix-bound β-glucans, increasing the amount in the wort.[8][19]

- Endo-(1,3;1,4)-β-glucanase (optimal 48°C, pH 4.7) degrades soluble high-molecular-weight β-glucan into low-molecular-weight β-glucan.[8][20]

- Endo-(1,3)-β-glucanase degrades soluble high-molecular-weight β-glucan into low-molecular-weight β-glucan, and may also help solubilize β-glucan.[21][22]

- Endo-(1,4)-β-glucanase AKA cellulase degrades soluble high-molecular-weight β-glucan (including cellulose) into low-molecular-weight β-glucan.[21][22][23]

- Exo-β-glucanase (optimal <40°C pH 4.5) degrades glucose from the ends of β-glucan.[8][22]

- Phosphate liberation (see Phosphates)

- Lipid degradation and oxidation (see Lipids)

- Lipase (optimal 55–65°C, pH 6.8–7.0) degrades lipids & lipid hydroperoxides into glycerine plus free fatty acids, and/or hydroperoxides.[8][24][25][23]

- Lipoxygenases (optimal 45–55°C, pH 6.3–7.0) oxidizes fatty acids into fatty acids hydroperoxides.[8][24][23] The function of lipoxygenase (LOX) during mashing is rather controversial. Lipoxygenase is suggested to be heat labile because only a minor part of the activity present in green malt survives kilning. However, this remaining part of LOX is known to be very stable towards heating. Almost 60% of the LOX activity of malt extract can survive for 1 h at a temperature of 67°C. LOX may survive temperatures as high as 95°C in spent grains. In addition, lipoxygenase purified from germinating barley has a pH optimum at 6.5.[26]

- Hydroperoxide lyase transforms lipid hydroperoxides through a series of steps into staling compounds such as trans-2-nonenal.[23]

- Phenolic compound release or oxidation (see Phenolic compounds, Oxidation)

- Polyphenol oxidase (optimal 60–65°C, pH 6.5–7.0) oxidizes polyphenols, especially lower molecular weight polyphenols (e.g. catechin).[8][27][28][9] Polyphenol oxidase loses activity during malting, being largely destroyed by kilning (although still active in pils malt), and it may be entirely destroyed depending on the temperature (even in pale malt).[29] Polyphenol oxidase is able to catalyze the oxidation of polyphenol compounds with oxygen into very reactive quinonic compounds.[30] Polyphenol oxidase is the main responsible for the enzymatic browning in fruits and vegetables.[30] PPO is totally destroyed during malting.[31]

- Feruloyl esterase AKA ferulic acid esterase AKA cinnamoyl esterase (optimal activity 40–50°C, pH 5.2–6.6) liberates phenolic acids (mainly ferulic acid) from arabinoxylans.[9][32] Inactive at 65°C and above.[33]

- β(1-4)-endoxylanase releases xylooligosaccharides[32]

- β-D-xylosidase releases xylose and xylooligosaccharides[32]

- α-L-arabinofuranosidase releases the corresponding furanosidase[32]

- Peroxidase (optimal >60°C, pH 6.2) generates free radicals from various organic and inorganic substrates.[8] Requires iron coenzyme.[3] Peroxidase can retain its activity even at 80°C.[26] Peroxidases catalyze the oxidation of polyphenols.[9] Barley malt contains remarkably high activity of the many peroxidase iso-enzymes, giving evidence for the importance of hydrogen peroxide reactions.[34] Peroxidases are considered to act mostly on the oxidation of polyphenols.[26] Many different peroxidases exist and vary by the variety of barley.[35]

- Other

- Endo-xylanase, exo-xylanase, and arabinosidases (optimal 45°C) degrade pentosans.[9]

- Pentosan solubilase releases bound pentosans.[9]

- Phosphorylase cleaves the terminal alpha-(1, 4) links in non-reducing chain ends with inorganic phosphate to release glucose-1-phosphate. Apparently its possible role in mashing has never been investigated.[3]

- Catalase catalyses the conversion of peroxides to water and ground state (unreactive) oxygen, however it is rapidly destroyed during mashing at 149°F (65°C) and therefore it is largely irrelevant in the brewhouse.[36] inactivated rapidly during mashing at 65°C.[26] catalase - inactivated rapidly during mashing at 65°C.[26] Catalase is denatured during mashing at 65C.[29] 2H2O2 --> 2 H2O + O2

- Superoxide dismutase catalyses the formation of peroxides from superoxides which in the absence of catalase leads to the formation of the hydroxyl radical.[36] inactivated rapidly during mashing at 65°C.[26] superoxide dismutase - inactivated rapidly during mashing at 65°C.[26] SOD is destroyed within 15 minutes of mashing at 65C.[29] 2O2- + 2H+ --> O2 + H2O2

- Oxalate oxidase (AKA germin) - catalyses the conversion of oxalate into carbon dioxide and hydrogen peroxide. pH optimum of approximately 4.0 but active over a large range. Because the enzyme is active in a broad pH range, and because it has high heat tolerance, it was active during mashing, but it was less important than other oxidases for scavenging oxygen from mashes because of its low affinity for oxygen.[37] Active during mashing[18]

- Ascorbate (per)oxidase (optimal pH 5.5) - catalyzes the oxidation of ascorbic acid by hydrogen peroxide.[37] Highly active during mashing.[18]

- Ascorbic acid oxidase (optimal pH 7.0, but active in a large range) - catalyzes the oxidation of ascorbic acid by O2.[37]

Fermentation[edit]

Coming eventually

- Yeast enzymes

- Invertase breaks sucrose into its constituents glucose and fructose.

- Phenolic acid decarboxylase (PAD; also known as ferulic acid decarboxylase, courmaric acid decarboxylase, cinnamate decarboxylase) catalyzes the enzymatic decarboxylation of HCAs to their vinyl derivatives. PAD is present in a wide variety of bacteria and fungi. These include species which represent contaminants in a brewing environment, but also species and strains utilized in brewing, such as many strains of brewer's yeast (Saccharomyces cerevisiae), as well as Brettanomyces sp., Lactobacillus, and Pediococcus.[38]

- Phenylacrylic acid decarboxylase (PAD1) is not actually a decarboxylase, but catalyzes the synthesis of an FMN-related co-factor required for the function of FDC1[38]

- Ferulic acid decarboxylase (FDC1) catalyzes the decarboxylation of cinnamic acid and derivatives.[38]

Added enzymes[edit]

A variety of enzyme products ("exogenous" enzymes) are available to home brewers for various purposes such as increasing starch/dextrin degradation or decreasing haze.

General information:

Storage - Enzyme preparations are not stable, so they should be stored cool and used fresh since the activity decreases over time.[3][39] Refer to the manufacturer for specific recommendations.

Impurities - Enzyme products are created by living organisms.[23] Therefore these products are not "pure", and will usually contain other substances such as residual materials from the nutrient medium in which the microbes were cultured, other enzymes besides the one(s) specified, diluents, extenders or carriers, and preservatives. Be aware that these impurities can potentially lead to haze formation, deterioration of beer foam, and loss of yeast flocculation. Modern enzyme products usually do NOT contain viable microbes.[3][39]

Product comparison - Products from different suppliers should be considered distinct, and it can be difficult to make comparisons between them due to lack of standardization. Also, the action of enzyme products can be greatly influenced by the usage conditions (e.g. temperature and pH), and therefore the results may vary between different brews. Consequently, the effectiveness of the addition of an enzyme preparation must be determined by brewers under their particular processing conditions.[3]

Common products:

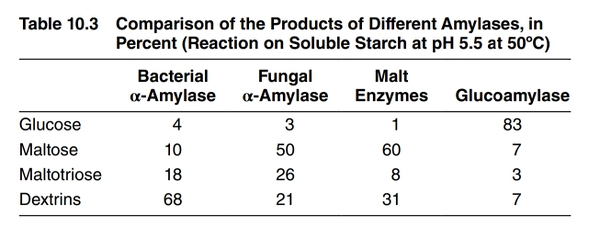

- Amylase (bacterial) - Degrades starch to dextrins very effectively but does not produce much fermentable sugar. Used mainly for liquefaction of adjunct starch.[39] See Bacterial alpha amylase.

- Fungal Alpha Amylase - Degrades larger dextrins, producing limit dextrins plus some fermentable sugars. Used to mildly increase fermentability. See Fungal alpha amylase.

- Glucoamylase - Degrades dextrins to produce mostly glucose, greatly increasing fermentability. Used to produce dry beer (e.g. "Brut IPA"), low-carb beer, or to accelerate sour beer production. See Glucoamylase.

- Clarity Ferm AKA Clearzyme AKA Clarex? is a proline-specific endoprotease that reduces chill haze and reduces "gluten"[23]

- Glucabuster

- Lysovin (lysozyme)

- Alpha galactosidase from AIH

- ferulic acid esterase products - can be used to increase release of phenolic acids during mashing[40]

See also[edit]

Potential sources

- http://themodernbrewhouse.com/forum/viewtopic.php?f=11&t=1821

- Amino Acid Permeases and their Influence on Flavour Compounds in Beer

- https://scholar.google.com/scholar?hl=en&as_sdt=1%2C36&q=sun+A+quantitative+assessment+of+the+importance+of+barley+seed+alpha-amylase%2C+beta-amylase%2C+debranching+enzyme+and+alpha-glucosidase+in+starch+degradation.&btnG=#d=gs_qabs&u=%23p%3DRr5Dbt7Zj7MJ

- https://www.researchgate.net/profile/Ahmed_Gomaa35/publication/323252887_Application_of_Enzymes_in_Brewing/links/5b5f33ae458515c4b2531f59/Application-of-Enzymes-in-Brewing.pdf

- https://hibernianbrewingschool.ie/wp-content/uploads/2015/09/The-role-of-enzymes-IOB.pdf

- http://www.knudsenbeverageconsulting.com/wp-content/uploads/2011/mbaa/mbaarmdpresentationenzymesinbrewing51102.pdf

- http://themodernbrewhouse.com/forum/viewtopic.php?f=11&t=2168

- https://www.themodernbrewhouse.com//forum/download/file.php?id=1931

- https://prowm.com/wp-content/uploads/2019/06/PRO-Tech-Notes-ISSUE-6-VOLUME-2.pdf

- https://www.researchgate.net/profile/Ahmed_Gomaa35/publication/323252887_Application_of_Enzymes_in_Brewing/links/5b5f33ae458515c4b2531f59/Application-of-Enzymes-in-Brewing.pdf

- Scheffler, A. and Bamforth, C.W. (2005) Exogenous β-glucanases and pentosanases and their impact on mashing, Enzym. Microb. Tech. 36, 813–817.

- Bamforth, C.W. (2010) The enzymology of cell wall breakdown during malting and mashing: An overview, Tech. Q. Mast. Brew. Assoc. Am.

References[edit]

- ↑ a b c d e f g h Kunze W. Wort production. In: Hendel O, ed. Technology Brewing & Malting. 6th ed. VBL Berlin; 2019. p. 230.

- ↑ Mosher M, Trantham K. Brewing Science: A Multidisciplinary Approach. 2nd ed. Springer; 2021.

- ↑ a b c d e f g h i Briggs DE, Boulton CA, Brookes PA, Stevens R. Brewing Science and Practice. Woodhead Publishing Limited and CRC Press LLC; 2004.

- ↑ a b c Fix G. Principles of Brewing Science. 2nd ed. Brewers Publications; 1999.

- ↑ Kunze, Wolfgang. Technology Brewing & Malting. Edited by Olaf Hendel, 6th English Ed., VBL Berlin, 2019. p. 54.

- ↑ Benešová K, Běláková S, Mikulíková R, Svoboda Z. Activity of proteolytic enzymes during malting and brewing. Kvasný Prům. 2017;63(1):2–7.

- ↑ Szwajgier D. Dry and wet milling of malt. A preliminary study comparing fermentable sugar, total protein, total phenolics and the ferulic acid content in non-hopped worts. J Inst Brew. 2011;117(4):569–577.

- ↑ a b c d e f g h i j k l m n o p Krottenthaler M, Back W, Zarnkow M. Wort production. In: Esslinger HM, ed. Handbook of Brewing: Processes, Technology, Markets. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.

- ↑ a b c d e f g h i j k l Narziss L, Back W, Gastl M, Zarnkow M. Abriss der Bierbrauerei. 8th ed. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2017.

- ↑ a b c Visser MJ. Evaluation of malted barley with different degrees of fermentability using the Rapid Visco Analyser (RVA). University of Stellenbosch. 2011.

- ↑ a b Evans DE, Fox GP. Comparison of diastatic power enzyme release and persistence during modified Institute of Brewing 65°C and Congress programmed mashes. J Am Soc Brew Chem. 2017;75(4):302–311.

- ↑ McCafferty CA, Jenkinson HR, Brosnan JM, Bryce JH. Limit dextrinase — Does its malt activity relate to its activity during brewing? J Inst Brew. 2004;110(4):284–296.

- ↑ a b Guerra NP, Torrado-Agrasar A, López-Macías C, et al. Use of Amylolytic Enzymes in Brewing. In: Preedy VR, ed. Beer in Health and Disease Prevention. Academic Press; 2009:113–126.

- ↑ Bamforth CW, Fox GP. Critical aspects of starch in brewing. BrewingScience. 2020;73:126–139.

- ↑ Im H, Henson CA. Characterization of high pI α-glucosidase from germinated barley seeds: substrate specificity, subsite affinities and active-site residues. Carbohydr Res. 1995;277(1):145–159.

- ↑ Andriotis VME, Saalbach G, Waugh R, Field RA, Smith AM. The Maltase Involved in Starch Metabolism in Barley Endosperm Is Encoded by a Single Gene. PLoS ONE. 2016;11(3):1–13

- ↑ Vriesekoop F, Rathband A, MacKinlay J, Bryce JH. The evolution of dextrins during the mashing and fermentation of all-malt whisky production. J Inst Brew. 2010;116(3):230–238.

- ↑ a b c Kanauchi M, Bamforth CW. A Challenge in the study of flavour instability. BrewingScience - Monatsschrift Brauwiss. 2018;71(Sept/Oct):82–84.

- ↑ a b c Sacher B, Becker T, Narziss L. Some reflections on mashing – Part 2. Brauwelt International. 2016;6:392-397.

- ↑ Jin YL, Speers RA, Paulson AT, Stewart RJ. Barley β-glucans and their degradation during malting and brewing. Tech Q Master Brew Assoc Am. 2004;41(3):231–240.

- ↑ a b Muller R. Factors influencing the stability of barley malt β-glucanase during mashing. J Am Soc Brew Chem. 1995;53(3):136–140.

- ↑ a b c Kanauchi M, Bamforth CW. The relevance of different enzymes for the hydrolysis of β-glucans in malting and mashing. J Inst Brew. 2008;114(3);224–229.

- ↑ a b c d e f Evans E. Mashing. American Society of Brewing Chemists and Master Brewers Association of the Americas; 2021.

- ↑ a b Golston AM. The impact of barley lipids on the brewing process and final beer quality: A mini-review. Tech Q Master Brew Assoc Am. 2021;58(1):43–51.

- ↑ Schwarz P, Stanley P, Solberg S. Activity of lipase during mashing. J Am Soc Brew Chem. 2002;60(3):107–109.

- ↑ a b c d e f g Pöyri S, Mikola M, Sontag-Strohm T, Kaukovirta-Norja A, Home S. The formation and hydrolysis of barley malt gel-protein under different mashing conditions. J Inst Brew. 2002;108(2):261–267.

- ↑ Quinde-Axtell Z, Baik BK. Phenolic compounds of barley grain and their implication in food product discoloration. J Agric Food Chem. 2006;54(26):9978–9984.

- ↑ Quinde-Axtell Z, Powers J. Baik BK. Retardation of discoloration in barley flour gel and dough. Cereal Chem. 2006;83(4):385–390.

- ↑ a b c Clarkson SP, Large SJ, Bamforth CW. Oxygen-scavenging enzymes in barley and malt and their effects during mashing. J Inst Brew. 1992;98(2):111–115.

- ↑ a b Carvalho DO, Gonçalves LM, Guido LF. Overall antioxidant properties of malt and how they are influenced by the individual constituents of barley and the malting process. Compr Rev Food Sci Food Saf. 2016;15(5):927–943.

- ↑ Billaud C, Garcia R, Kohler B, Néron S, Boivin P, Nicolas J. Possible implications of four oxidoreductases (polyphenoloxidase, catalase, lipoxygenase, and peroxidase) present in brewery's barley and malt on organoleptic and rheological properties of mash and beer. In: VTT SYMPOSIUM 2000;207:247–250.

- ↑ a b c d Schwarz KJ, Boitz LI, Methner FJ. Release of phenolic acids and amino acids during mashing dependent on temperature, pH, time, and raw materials. J Am Soc Brew Chem. 2012;70(4):290–295.

- ↑ Wannenmacher J, Gastl M, Becker T. Phenolic substances in beer: Structural diversity, reactive potential and relevance for brewing process and beer quality. Compr Rev Food Sci Food Saf. 2018;17(4):953–988.

- ↑ Muller R. The formation of hydrogen peroxide during oxidation of thiol-containing proteins. J Inst Brew. 1997;103(5):307–310.

- ↑ Mahalingam R. Shotgun proteomics of the barley seed proteome. BMC Genomics. 2017;18(44).

- ↑ a b EtokAkpan OU. Preliminary study of fat oxidation in sorghum and maize brewing. World J Microbiol Biotechnol. 2004;20:569–573.

- ↑ a b c Kanauchi M. Oxidative enzyme effects in malt for brewing. In: Kanauchi M, ed. Brewing Technology. IntechOpen. 2017:29–47.

- ↑ a b c Lentz M. The impact of simple phenolic compounds on beer aroma and flavor. Fermentation. 2018;4(1):20.

- ↑ a b c Ryder DS. Processing aids in brewing. In: Stewart GG, Russell I, Anstruther A, eds. Handbook of Brewing. 3rd ed. CRC Press; 2017.

- ↑ https://onlinelibrary.wiley.com/doi/epdf/10.1002/j.2050-0416.2011.tb00489.x