Starch

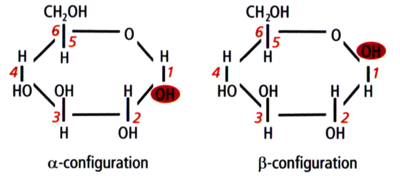

Starch is the main carbohydrate in cereal grains and it can be considered to be the most important malt component. To make beer, the starch in the grain is first broken apart by milling. The exposed starch then undergoes changes during mashing including gelatinization, liquefaction, and finally saccharification. This degradation process yields fermentable and non-fermentable sugars. The fermentable sugars ultimately become alcohol and carbon dioxide gas. If the starch degradation is incomplete for some reason, intact starch molecules can cause a hazy beer. Starch and its polysaccharide degradation products are sometimes called α-glucans, because of the alpha linkages they contain (β-glucans have beta linkages between the glucose units).

-

Glucose in alpha and beta configurations

-

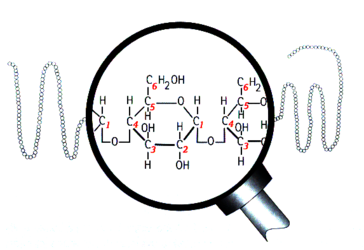

Structure of amylose

-

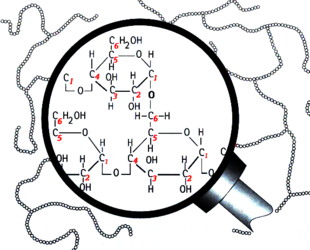

Branching in the structure of amylopectin

Structurally, starch is a polymer of glucose that can be classified into two categories: amylose and amylopectin. Amylose makes up 20–30% of the starch in barley and it consists of long unbranched or slightly-branched chains.[1][2] The rest is amylopectin, a much larger molecule consisting of branching chains.[3][4][5][6][7] Learning the types of bonds within the starch molecules is important to understand enzyme activity in the mash and ultimately the makeup of wort and beer. The most common bond between the glucose units in starch is the α-1,4 glucosidic bond, which forms a straight chain. Branch points are formed by α-1,6 glucosidic bonds. FYI, this bond naming convention comes from the numbering of the carbon atoms in the glucose molecule. For example, 1,4 bonds are a connection between the 1st and 4th carbons of adjacent glucose units (see the above illustrations). The branch points are responsible for the unfermentable sugars (dextrins) in wort because the active enzymes in the mash generally cannot break down the starch molecules near a branch (see Saccharification). Therefore, the degree of starch branching is a key variable that may impact beer quality, but unfortunately it is not measured by maltsters or brewers.[7]

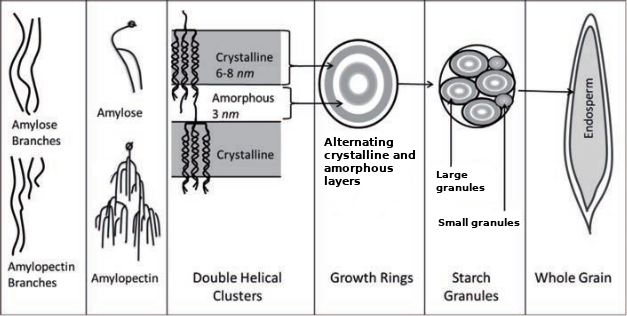

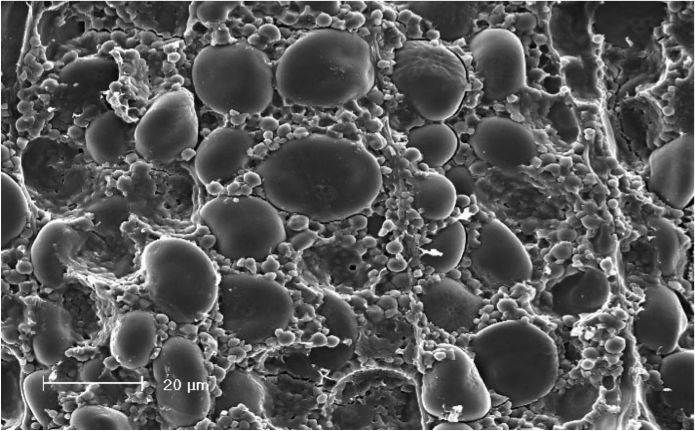

In cereal grain, the starch molecules form layers of crystalline and amorphous structure in order to create granules, which make up the endosperm.[8] Starch granules in barley can be divided into two or even three fractions, with average particle sizes of 20 µm (large), 7.5 µm (medium) and 2.3 µm (small). These types of barley starch granules are characterized by different amylose:amylopectin ratios, as well as different structures and properties—starch gelatinization temperature in particular.[9][10] The "large" starch granules contain approximately 90% of the starch mass.[11] This information is useful to help understand the impact that granule sizes have on gelatinization, namely that the "small" granules have a significantly higher gelatinization temperature, which may ultimately require a step mash to extract.[12][2]

Science

Unlike the above information, this isn't quite so useful or necessary for understanding the brewing process, but it may be interesting to some brewers.

The ends of the starch chains differ in their structure due to the nature of the glucose molecule. In scientific terms, amylose has one non-reducing end (NRE) and one reducing end (RE), and amylopectin has many NREs and just one RE.[13] Carbon 1 is the RE and carbon 4 is the NRE. The difference in chemistry affects the enzyme activity at the end of the chain (see Saccharification).

See also

To review:

References

- ↑ Buléon A, Colonna P, Planchot V, Ball S. Starch granules: structure and biosynthesis. Int J Biol Macromol. 1998;23(2):85–112.

- ↑ a b Bamforth CW, Fox GP. Critical aspects of starch in brewing. BrewingScience. 2020;73:126–139.

- ↑ Kunze W. Raw materials. In: Hendel O, ed. Technology Brewing & Malting. 6th ed. VBL Berlin; 2019:39–107.

- ↑ Meussdoerffer F, Zarnkow M. Starchy raw materials. In: Esslinger HM, ed. Handbook of Brewing: Processes, Technology, Markets. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.

- ↑ Miedl-Appelbee M. Brewhouse technology. In: Stewart GG, Russell I, Anstruther A, eds. Handbook of Brewing. 3rd ed. CRC Press; 2017.

- ↑ Holbrook CJ. Brewhouse operations. In: Smart C, ed. The Craft Brewing Handbook. Woodhead Publishing; 2019.

- ↑ a b Fox GP. Starch in brewing applications. In: Sjöö M, Nilsson L, eds. Starch in Food. 2nd ed. Woodhead Publishing; 2017:633–659.

- ↑ Ratnayake WS, Jackson DS. Starch Gelatinization. In: Advances in Food and Nutrition Research. Academic Press; 2008;55:221–268.

- ↑ Szwajgier D. "Dry and wet milling of malt. A preliminary study comparing fermentable sugar, total protein, total phenolics and the ferulic acid content in non-hopped worts." J Inst Brew. 2011;117(4):569–577.

- ↑ Yu W, Zhai H, Xia G, et al. Starch fine molecular structures as a significant controller of the malting, mashing, and fermentation performance during beer production. Trends Food Sci Technol. 2020;105:296–307.

- ↑ Krottenthaler M, Back W, Zarnkow M. Wort production. In: Esslinger HM, ed. Handbook of Brewing: Processes, Technology, Markets. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.

- ↑ Keßler M, Kreisz S, Zarnkow M, Back, W. Do brewers need a starch modification index? Brauwelt International. 2008;1:52–55.

- ↑ Lewis MJ, Young TW. Brewing. Springer; 2001:234.