Starch: Difference between revisions

(combining pages) |

No edit summary |

||

| Line 1: | Line 1: | ||

Starch is the main [[carbohydrates|carbohydrate]] in cereal [[grain]]s and it can be considered to be the most important [[malt]] component. To make beer, the starch in the grain is first broken apart by [[milling]]. The exposed starch then undergoes changes during [[mashing]] including | Starch is the main [[carbohydrates|carbohydrate]] in cereal [[grain]]s and it can be considered to be the most important [[malt]] component. To make beer, the starch in the grain is first broken apart by [[milling]]. The exposed starch then undergoes changes during [[mashing]] including gelatinization, liquefaction, and finally saccharification. This degradation process yields fermentable and non-fermentable [[sugars]]. The fermentable sugars ultimately become alcohol and carbon dioxide gas. If the starch degradation is incomplete for some reason, intact starch molecules can cause a [[haze|hazy]] beer. Starch and its polysaccharide degradation products are sometimes called α-glucans, because of the alpha linkages they contain ([[beta-glucans|β-glucans]] have beta linkages between the glucose units). | ||

== Starch structure and organization == | == Starch structure and organization == | ||

| Line 8: | Line 8: | ||

File:Starch-amylopectin.png|Branching in the structure of amylopectin | File:Starch-amylopectin.png|Branching in the structure of amylopectin | ||

</gallery> | </gallery> | ||

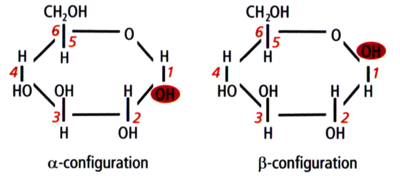

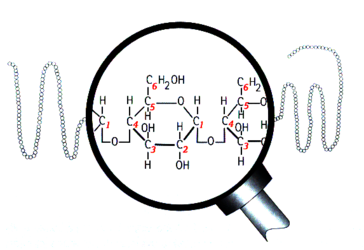

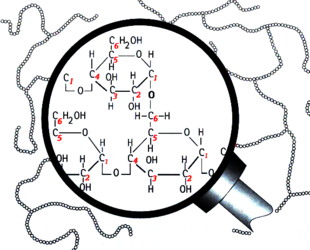

Structurally, starch is a polymer of [[sugars|glucose]] that can be classified into two categories: amylose and amylopectin. Amylose makes up 20–30% of the starch in barley and it consists of long unbranched or slightly-branched chains.<ref name=buleon>Buléon A, Colonna P, Planchot V, Ball S. [https://www.sciencedirect.com/science/article/abs/pii/S0141813098000403 Starch granules: structure and biosynthesis.] ''Int J Biol Macromol.'' 1998;23(2):85–112.</ref><ref name=crit/><ref name=mashing>Evans E. [[Library|''Mashing.'']] American Society of Brewing Chemists and Master Brewers Association of the Americas; 2021.</ref> The rest is amylopectin, a much larger molecule consisting of branching chains.<ref name=kunzeraw>Kunze W. Raw materials. In: Hendel O, ed. [[Library|''Technology Brewing & Malting.'']] 6th ed. VLB Berlin; 2019:39–107.</ref><ref>Meussdoerffer F, Zarnkow M. Starchy raw materials. In: Esslinger HM, ed. [[Library|''Handbook of Brewing: Processes, Technology, Markets.'']] Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.</ref><ref name=hob11>Miedl-Appelbee M. Brewhouse technology. In: Stewart GG, Russell I, Anstruther A, eds. [[Library|''Handbook of Brewing.'']] 3rd ed. CRC Press; 2017.</ref><ref name=smart3>Holbrook CJ. Brewhouse operations. In: Smart C, ed. [[Library|''The Craft Brewing Handbook.'']] Woodhead Publishing; 2019.</ref><ref name=fox>Fox GP. Starch in brewing applications. In: Sjöö M, Nilsson L, eds. ''Starch in Food.'' 2nd ed. Woodhead Publishing; 2017:633–659.</ref> Learning the types of bonds within the starch molecules is important to understand enzyme activity in the mash and ultimately the makeup of wort and beer. The most common bond between the glucose units in starch is the α-1,4 glucosidic bond, which forms a straight chain. Branch points are formed by α-1,6 glucosidic bonds. FYI, this bond naming convention comes from the numbering of the carbon atoms in the glucose molecule. For example, 1,4 bonds are a connection between the 1<sup>st</sup> and 4<sup>th</sup> carbons of adjacent glucose units (see the above illustrations). The branch points are responsible for the unfermentable sugars (dextrins) in wort because the active [[enzymes]] in the mash generally cannot break down the starch molecules near a branch | Structurally, starch is a polymer of [[sugars|glucose]] that can be classified into two categories: amylose and amylopectin. Amylose makes up 20–30% of the starch in barley and it consists of long unbranched or slightly-branched chains.<ref name=buleon>Buléon A, Colonna P, Planchot V, Ball S. [https://www.sciencedirect.com/science/article/abs/pii/S0141813098000403 Starch granules: structure and biosynthesis.] ''Int J Biol Macromol.'' 1998;23(2):85–112.</ref><ref name=crit/><ref name=mashing>Evans E. [[Library|''Mashing.'']] American Society of Brewing Chemists and Master Brewers Association of the Americas; 2021.</ref> The rest is amylopectin, a much larger molecule consisting of branching chains.<ref name=kunzeraw>Kunze W. Raw materials. In: Hendel O, ed. [[Library|''Technology Brewing & Malting.'']] 6th ed. VLB Berlin; 2019:39–107.</ref><ref>Meussdoerffer F, Zarnkow M. Starchy raw materials. In: Esslinger HM, ed. [[Library|''Handbook of Brewing: Processes, Technology, Markets.'']] Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.</ref><ref name=hob11>Miedl-Appelbee M. Brewhouse technology. In: Stewart GG, Russell I, Anstruther A, eds. [[Library|''Handbook of Brewing.'']] 3rd ed. CRC Press; 2017.</ref><ref name=smart3>Holbrook CJ. Brewhouse operations. In: Smart C, ed. [[Library|''The Craft Brewing Handbook.'']] Woodhead Publishing; 2019.</ref><ref name=fox>Fox GP. Starch in brewing applications. In: Sjöö M, Nilsson L, eds. ''Starch in Food.'' 2nd ed. Woodhead Publishing; 2017:633–659.</ref> Learning the types of bonds within the starch molecules is important to understand enzyme activity in the mash and ultimately the makeup of wort and beer. The most common bond between the glucose units in starch is the α-1,4 glucosidic bond, which forms a straight chain. Branch points are formed by α-1,6 glucosidic bonds. FYI, this bond naming convention comes from the numbering of the carbon atoms in the glucose molecule. For example, 1,4 bonds are a connection between the 1<sup>st</sup> and 4<sup>th</sup> carbons of adjacent glucose units (see the above illustrations). The branch points are responsible for the unfermentable sugars (dextrins) in wort because the active [[enzymes]] in the mash generally cannot break down the starch molecules near a branch. Therefore, the degree of starch branching is a key variable that may impact beer quality, but unfortunately it is not measured by maltsters or brewers.<ref name=fox/> | ||

[[File:Starch-structure.png|frame|left|Starch structure hierarchy. Image modified from Bamforth and Fox (2020)]] | [[File:Starch-structure.png|frame|left|Starch structure hierarchy. Image modified from Bamforth and Fox (2020)]] | ||

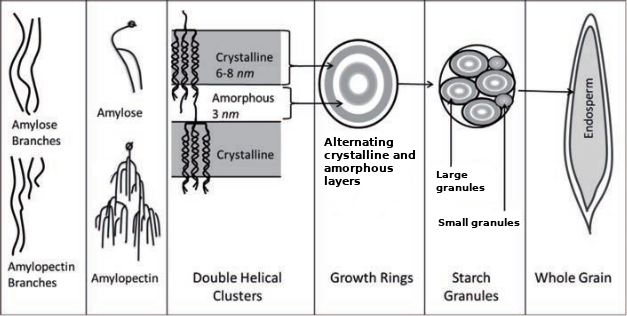

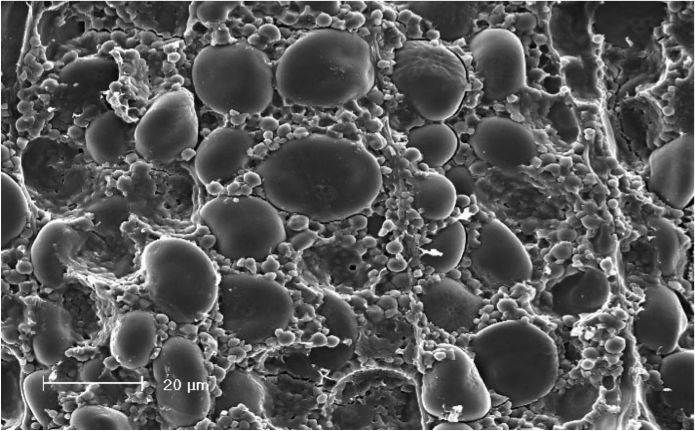

In cereal [[grain]], the starch molecules form layers of crystalline and amorphous structure in order to create granules, which make up the endosperm.<ref name=ratnayake>Ratnayake WS, Jackson DS. [https://www.sciencedirect.com/science/article/pii/S1043452608004051 Starch Gelatinization.] In: ''Advances in Food and Nutrition Research''. Academic Press; 2008;55:221–268.</ref> Starch granules in barley can be divided into two fractions, with average particle sizes of around 20 µm for large granules and 2 µm for small granules.<ref>Chmelík J, Krumlová A, Budinská M, et al. [https://onlinelibrary.wiley.com/doi/abs/10.1002/j.2050-0416.2001.tb00074.x Comparison of size characterization of barley starch granules determined by electron and optical microscopy, low angle laser light scattering and gravitational field-flow fractionation.] ''J Inst Brew.'' 2001;107(1).</ref><ref name=mashing/> These types of barley starch granules are characterized by different amylose:amylopectin ratios, as well as different structures and properties—starch | In cereal [[grain]], the starch molecules form layers of crystalline and amorphous structure in order to create granules, which make up the endosperm.<ref name=ratnayake>Ratnayake WS, Jackson DS. [https://www.sciencedirect.com/science/article/pii/S1043452608004051 Starch Gelatinization.] In: ''Advances in Food and Nutrition Research''. Academic Press; 2008;55:221–268.</ref> Starch granules in barley can be divided into two fractions, with average particle sizes of around 20 µm for large granules and 2 µm for small granules.<ref>Chmelík J, Krumlová A, Budinská M, et al. [https://onlinelibrary.wiley.com/doi/abs/10.1002/j.2050-0416.2001.tb00074.x Comparison of size characterization of barley starch granules determined by electron and optical microscopy, low angle laser light scattering and gravitational field-flow fractionation.] ''J Inst Brew.'' 2001;107(1).</ref><ref name=mashing/> These types of barley starch granules are characterized by different amylose:amylopectin ratios, as well as different structures and properties—starch gelatinization temperature in particular.<ref>Szwajgier D. [https://onlinelibrary.wiley.com/doi/pdf/10.1002/j.2050-0416.2011.tb00505.x "Dry and wet milling of malt. A preliminary study comparing fermentable sugar, total protein, total phenolics and the ferulic acid content in non-hopped worts."] ''J Inst Brew.'' 2011;117(4):569–577.</ref><ref name=yu>Yu W, Zhai H, Xia G, et al. [https://www.sciencedirect.com/science/article/abs/pii/S0924224420306002 Starch fine molecular structures as a significant controller of the malting, mashing, and fermentation performance during beer production.] ''Trends Food Sci Technol.'' 2020;105:296–307.</ref> The "large" starch granules contain 70–95% of the starch mass.<ref>Krottenthaler M, Back W, Zarnkow M. Wort production. In: Esslinger HM, ed. [[Library|''Handbook of Brewing: Processes, Technology, Markets.'']] Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.</ref><ref>Langenaeken NA, De Schepper CF, De Schutter DP, Courtin CM. [https://www.sciencedirect.com/science/article/abs/pii/S030881461930843X Different gelatinization characteristics of small and large barley starch granules impact their enzymatic hydrolysis and sugar production during mashing.] ''Food Chem.'' 2019;295:138–146.</ref> This information is useful to help understand the impact that granule sizes have on gelatinization, namely that the "small" granules have a significantly higher gelatinization temperature, which may ultimately require a step mash to extract.<ref>Keßler M, Kreisz S, Zarnkow M, Back, W. [http://www.lowoxygenbrewing.com/wp-content/uploads/2017/04/dawddpdf.pdf Do brewers need a starch modification index?] ''Brauwelt International.'' 2008;1:52–55.</ref><ref name=crit/><ref>Slack PT, Baxter ED, Wainwright T. [https://onlinelibrary.wiley.com/doi/pdf/10.1002/j.2050-0416.1979.tb06837.x Inhibition by hordein of starch degradation.] ''J Inst Brew.'' 1979;85(2):112–114.</ref><ref>Cozzolino D, Degner S. [https://www.sciencedirect.com/science/article/abs/pii/S0963996916300047 An overview on the role of lipids and fatty acids in barley grain and their products during beer brewing.] ''Food Res Int.'' 2016;81:114–121.</ref> | ||

[[File:Barley-starch-granules.png|frame|left|A scanning electron micrograph showing the large and small starch granules in barley. Photo from feedxl.com]]<br clear="all" /> | [[File:Barley-starch-granules.png|frame|left|A scanning electron micrograph showing the large and small starch granules in barley. Photo from feedxl.com]]<br clear="all" /> | ||

==Science== | ==Science== | ||

The ends of the starch chains differ in their structure due to the asymmetrical nature of the glucose molecule. Carbon 1 of the glucose unit is the "reducing end" (RE) and carbon 4 is the "non-reducing end" (NRE). Amylose has one RE and one NRE, while amylopectin has one RE and many NREs.<ref>Lewis MJ, Young TW. ''Brewing.'' Springer; 2001:234.</ref> The ends differ in their chemistry and shape, which affects how the enzymes interact with the ends of the chains | The ends of the starch chains differ in their structure due to the asymmetrical nature of the glucose molecule. Carbon 1 of the glucose unit is the "reducing end" (RE) and carbon 4 is the "non-reducing end" (NRE). Amylose has one RE and one NRE, while amylopectin has one RE and many NREs.<ref>Lewis MJ, Young TW. ''Brewing.'' Springer; 2001:234.</ref> The ends differ in their chemistry and shape, which affects how the enzymes interact with the ends of the chains. | ||

== Gelatinization == | == Gelatinization == | ||

[[File:Starch-gelatinization.gif|frame|right|Starch gelatinization. Image from ''Advances in Food and Nutrition Research'' (2008).]] | [[File:Starch-gelatinization.gif|frame|right|Starch gelatinization. Image from ''Advances in Food and Nutrition Research'' (2008).]] | ||

Gelatinization (also called "pasting"), which typically occurs during [[mashing]], is the hydration of | Gelatinization (also called "pasting"), which typically occurs during [[mashing]], is the hydration of starch molecules. When exposed to hot water, starch granules swell and burst, losing their organized structure (think popcorn).<ref name=kunze/><ref name=esslinger>Krottenthaler M, Back W, Zarnkow M. Wort production. In: Esslinger HM, ed. [[Library|''Handbook of Brewing: Processes, Technology, Markets.'']] Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.</ref><ref name=fix>Fix G. [[Library|''Principles of Brewing Science.'']] 2nd ed. Brewers Publications; 1999.</ref><ref name=crit>Bamforth CW, Fox GP. [https://www.brewingscience.de/index.php?tpl=table_of_contents&year=2020&edition=0009%2F0010&article=92781 Critical aspects of starch in brewing.] ''BrewingScience.'' 2020;73(9/10):126–139.</ref> This physical process makes the starch much more accessible to [[enzymes]].<ref name=slack/><ref name=Mousia/><ref name=mashing/> If the starch is not fully gelatinized, it can potentially result in a lower [[efficiency|yield]], lower [[attenuation]], [[filtration]] difficulties, possible scorching, and starch [[haze]].<ref name=kunze/><ref name=slack/> Therefore, the gelatinization temperature is important to consider when choosing a mashing schedule.<ref name=sacher2/> In the mash, gelatinization is followed by liquefaction and saccharification, an enzymatic process. | ||

The gelatinization temperature of most [[grain|cereals]] is between 149–176°F (65–80°C). However, it drops noticeably in the presence of starch-degrading enzymes (i.e. in [[malt|malted]] grain).<ref name=kunze/> For example, [[barley]] malt starch normally begins to gelatinize at 138–142°F (59–61°C), although it is variable.<ref name=kunze>Kunze W. Wort Production. In: Hendel O, ed. [[Library|''Technology Brewing & Malting.'']] 6th ed. VLB Berlin; 2019:220–221.</ref><ref name=model>MacGregor AW, Bazin SL, Macri LJ, Babb JC. [https://www.sciencedirect.com/science/article/abs/pii/S0733521098902338 Modelling the contribution of ''alpha''-amylase, ''beta''-amylase and limit dextrinase to starch degradation during mashing.] ''J Cereal Sci.'' 1999;29(2):161–169.</ref> It's important to understand that not all of the starch in a batch gelatinizes at the same temperature.<ref name=mashing/> In particular, the "small" starch granules gelatinize at a significantly higher temperature than the majority of starch from the "large" granules | The gelatinization temperature of most [[grain|cereals]] is between 149–176°F (65–80°C). However, it drops noticeably in the presence of starch-degrading enzymes (i.e. in [[malt|malted]] grain).<ref name=kunze/> For example, [[barley]] malt starch normally begins to gelatinize at 138–142°F (59–61°C), although it is variable.<ref name=kunze>Kunze W. Wort Production. In: Hendel O, ed. [[Library|''Technology Brewing & Malting.'']] 6th ed. VLB Berlin; 2019:220–221.</ref><ref name=model>MacGregor AW, Bazin SL, Macri LJ, Babb JC. [https://www.sciencedirect.com/science/article/abs/pii/S0733521098902338 Modelling the contribution of ''alpha''-amylase, ''beta''-amylase and limit dextrinase to starch degradation during mashing.] ''J Cereal Sci.'' 1999;29(2):161–169.</ref> It's important to understand that not all of the starch in a batch gelatinizes at the same temperature.<ref name=mashing/> In particular, the "small" starch granules gelatinize at a significantly higher temperature than the majority of starch from the "large" granules, potentially as high as 186°F (80°C) in the case of barley malt.<ref name=esslinger/><ref name=Mousia/><ref>Langenaeken NA, De Schepper CF, De Schutter DP, Courtin CM. [https://www.sciencedirect.com/science/article/abs/pii/S030881461930843X Different gelatinization characteristics of small and large barley starch granules impact their enzymatic hydrolysis and sugar production during mashing.] ''Food Chem.'' 2019;295:138–146.</ref> Also be aware that different batches of grain will have slightly different gelatinization temperatures due to the effects of variable growth conditions and climatic influences.<ref name=sacher2/><ref name=adb/><ref name=pahl>Pahl R, Meyer B, Biurrun R. Wort and Wort Quality Parameters. In: Bamforth CW, ed. [[Library|''Brewing Materials and Processes: A Practical Approach to Beer Excellence.'']] Academic Press; 2016.</ref> Furthermore, the gelatinization temp can be influenced by [[milling]]—more intensive crushing lowers the gelatinization temperature.<ref name=Mousia>Mousia Z, Balkin RC, Pandiella SS, Webb C. [https://www.sciencedirect.com/science/article/pii/S0032959203004400 The effect of milling parameters on starch hydrolysis of milled malt in the brewing process.] ''Process Biochem.'' 2004;39(12):2213–2219.</ref><ref>Morrison WR, Tester RF, Gidley MJ. [https://www.sciencedirect.com/science/article/abs/pii/S0733521084710289 Properties of damaged starch granules. II. Crystallinity, molecular order and gelatinisation of ball-milled starches.] ''J Cereal Sci.'' 1994;19(3):209–217.</ref><ref>Warpala IWS, Pandiella SS. [https://www.sciencedirect.com/science/article/abs/pii/S0960308500701982 Grist fractionation and starch modification during the milling of malt.] ''Food and Bioproducts Processing.'' 2000;78(2):85–89.</ref> | ||

It can be problematic if too much starch in a batch of malt gelatinizes above 149°F (65°C).<ref name=mashing/> β-amylase and limit dextrinase are quickly inactivated above this threshold, which reduces the amount of starch degradation and therefore reduces the fermentability of the wort and/or decreases the yield | It can be problematic if too much starch in a batch of malt gelatinizes above 149°F (65°C).<ref name=mashing/> β-amylase and limit dextrinase are quickly inactivated above this threshold, which reduces the amount of starch degradation and therefore reduces the fermentability of the wort and/or decreases the yield.<ref name=evans>Evans DE, Fox GP. [https://www.tandfonline.com/doi/abs/10.1094/ASBCJ-2017-4707-01 Comparison of diastatic power enzyme release and persistence during modified Institute of Brewing 65°C and Congress programmed mashes]. ''J Am Soc Brew Chem.'' 2017;75(4):302–311.</ref><ref>Evans DE, Li C, Eglinton JK. [https://www.researchgate.net/publication/226691242_The_Properties_and_Genetics_of_Barley_Malt_Starch_Degrading_Enzymes The properties and genetics of barley malt starch degrading enzymes.] In: Zhang G, Li C, eds. [[Library|''Genetics and Improvement of Barley Malt Quality.'']] Springer; 2010:143–189.</ref> Even with a proper step mash, this may result in a lower final [[attenuation]] as well as negative effects on flavor and mouthfeel.<ref name=sacher2>Sacher B, Becker T, Narziss L. [http://www.lowoxygenbrewing.com/wp-content/uploads/2017/04/pddvxvf.pdf Some reflections on mashing – Part 2.] ''Brauwelt International.'' 2016;6:392-397.</ref><ref name=assessing>Evans DE, Collins H, Eglinton J, Wihelmson A. [https://www.tandfonline.com/doi/abs/10.1094/ASBCJ-63-0185 Assessing the impact of the level of diastatic power enzymes and their thermostability on the hydrolysis of starch during wort production to predict malt fermentability.] ''J Am Soc Brew Chem.'' 2005;63(4):185–198.</ref> | ||

For "micronized", "torrefied", and "flaked" grains, the starch is already gelatinized (as part of the production process) and these grain products can be added directly to a normal malt mash in reasonable quantities (see [[Adjuncts]]).<ref name=smart1>Howe S. Raw materials. In: Smart C, ed. [[Library|''The Craft Brewing Handbook.'']] Woodhead Publishing; 2019.</ref> With the exception of [[wheat]], [[oats]], and [[rye]], raw unmalted [[grain|cereals]] typically require a separate high-temperature gelatinization step to be used in a [[mashing|mash]] because the gelatinization temperature is too high to achieve during a normal mashing process (see [[Cereal mash]]).<ref name=fix/><ref name=mashing/> | For "micronized", "torrefied", and "flaked" grains, the starch is already gelatinized (as part of the production process) and these grain products can be added directly to a normal malt mash in reasonable quantities (see [[Adjuncts]]).<ref name=smart1>Howe S. Raw materials. In: Smart C, ed. [[Library|''The Craft Brewing Handbook.'']] Woodhead Publishing; 2019.</ref> With the exception of [[wheat]], [[oats]], and [[rye]], raw unmalted [[grain|cereals]] typically require a separate high-temperature gelatinization step to be used in a [[mashing|mash]] because the gelatinization temperature is too high to achieve during a normal mashing process (see [[Cereal mash]]).<ref name=fix/><ref name=mashing/> | ||

| Line 54: | Line 54: | ||

* [[Grain]] | * [[Grain]] | ||

* [[Mashing]] | * [[Mashing]] | ||

* [[Iodine test]] | * [[Iodine test]] | ||

* [[Sugars]] | * [[Sugars]] | ||

==References== | ==References== | ||

Revision as of 20:09, 22 February 2022

Starch is the main carbohydrate in cereal grains and it can be considered to be the most important malt component. To make beer, the starch in the grain is first broken apart by milling. The exposed starch then undergoes changes during mashing including gelatinization, liquefaction, and finally saccharification. This degradation process yields fermentable and non-fermentable sugars. The fermentable sugars ultimately become alcohol and carbon dioxide gas. If the starch degradation is incomplete for some reason, intact starch molecules can cause a hazy beer. Starch and its polysaccharide degradation products are sometimes called α-glucans, because of the alpha linkages they contain (β-glucans have beta linkages between the glucose units).

Starch structure and organization

-

Glucose in alpha and beta configurations

-

Structure of amylose

-

Branching in the structure of amylopectin

Structurally, starch is a polymer of glucose that can be classified into two categories: amylose and amylopectin. Amylose makes up 20–30% of the starch in barley and it consists of long unbranched or slightly-branched chains.[1][2][3] The rest is amylopectin, a much larger molecule consisting of branching chains.[4][5][6][7][8] Learning the types of bonds within the starch molecules is important to understand enzyme activity in the mash and ultimately the makeup of wort and beer. The most common bond between the glucose units in starch is the α-1,4 glucosidic bond, which forms a straight chain. Branch points are formed by α-1,6 glucosidic bonds. FYI, this bond naming convention comes from the numbering of the carbon atoms in the glucose molecule. For example, 1,4 bonds are a connection between the 1st and 4th carbons of adjacent glucose units (see the above illustrations). The branch points are responsible for the unfermentable sugars (dextrins) in wort because the active enzymes in the mash generally cannot break down the starch molecules near a branch. Therefore, the degree of starch branching is a key variable that may impact beer quality, but unfortunately it is not measured by maltsters or brewers.[8]

In cereal grain, the starch molecules form layers of crystalline and amorphous structure in order to create granules, which make up the endosperm.[9] Starch granules in barley can be divided into two fractions, with average particle sizes of around 20 µm for large granules and 2 µm for small granules.[10][3] These types of barley starch granules are characterized by different amylose:amylopectin ratios, as well as different structures and properties—starch gelatinization temperature in particular.[11][12] The "large" starch granules contain 70–95% of the starch mass.[13][14] This information is useful to help understand the impact that granule sizes have on gelatinization, namely that the "small" granules have a significantly higher gelatinization temperature, which may ultimately require a step mash to extract.[15][2][16][17]

Science

The ends of the starch chains differ in their structure due to the asymmetrical nature of the glucose molecule. Carbon 1 of the glucose unit is the "reducing end" (RE) and carbon 4 is the "non-reducing end" (NRE). Amylose has one RE and one NRE, while amylopectin has one RE and many NREs.[18] The ends differ in their chemistry and shape, which affects how the enzymes interact with the ends of the chains.

Gelatinization

Gelatinization (also called "pasting"), which typically occurs during mashing, is the hydration of starch molecules. When exposed to hot water, starch granules swell and burst, losing their organized structure (think popcorn).[19][20][21][2] This physical process makes the starch much more accessible to enzymes.[22][23][3] If the starch is not fully gelatinized, it can potentially result in a lower yield, lower attenuation, filtration difficulties, possible scorching, and starch haze.[19][22] Therefore, the gelatinization temperature is important to consider when choosing a mashing schedule.[24] In the mash, gelatinization is followed by liquefaction and saccharification, an enzymatic process.

The gelatinization temperature of most cereals is between 149–176°F (65–80°C). However, it drops noticeably in the presence of starch-degrading enzymes (i.e. in malted grain).[19] For example, barley malt starch normally begins to gelatinize at 138–142°F (59–61°C), although it is variable.[19][25] It's important to understand that not all of the starch in a batch gelatinizes at the same temperature.[3] In particular, the "small" starch granules gelatinize at a significantly higher temperature than the majority of starch from the "large" granules, potentially as high as 186°F (80°C) in the case of barley malt.[20][23][26] Also be aware that different batches of grain will have slightly different gelatinization temperatures due to the effects of variable growth conditions and climatic influences.[24][27][28] Furthermore, the gelatinization temp can be influenced by milling—more intensive crushing lowers the gelatinization temperature.[23][29][30]

It can be problematic if too much starch in a batch of malt gelatinizes above 149°F (65°C).[3] β-amylase and limit dextrinase are quickly inactivated above this threshold, which reduces the amount of starch degradation and therefore reduces the fermentability of the wort and/or decreases the yield.[31][32] Even with a proper step mash, this may result in a lower final attenuation as well as negative effects on flavor and mouthfeel.[24][33]

For "micronized", "torrefied", and "flaked" grains, the starch is already gelatinized (as part of the production process) and these grain products can be added directly to a normal malt mash in reasonable quantities (see Adjuncts).[34] With the exception of wheat, oats, and rye, raw unmalted cereals typically require a separate high-temperature gelatinization step to be used in a mash because the gelatinization temperature is too high to achieve during a normal mashing process (see Cereal mash).[21][3]

| Grain | Typical gelatinization temperature |

|---|---|

| Barley malt | 140–149°F (60–65°C)[20][21][22][27][35][36][3] |

| Wheat | 126–147°F (52–64°C)[35][3] |

| Oats | 126–147°F (52–64°C)[3] |

| Rye | 120–142°F (49–61°C)[3] |

| Maize | 143–176°F (62–80°C)[35][3] |

| Sorghum | 156–185°F (69–85°C)[35][3] |

| Rice | 142–180°F (61–82°C)[35][3] |

| Potato | 133–156°F (56–69°C)[35] |

See also

References

- ↑ Buléon A, Colonna P, Planchot V, Ball S. Starch granules: structure and biosynthesis. Int J Biol Macromol. 1998;23(2):85–112.

- ↑ a b c Bamforth CW, Fox GP. Critical aspects of starch in brewing. BrewingScience. 2020;73(9/10):126–139.

- ↑ a b c d e f g h i j k l m Evans E. Mashing. American Society of Brewing Chemists and Master Brewers Association of the Americas; 2021.

- ↑ Kunze W. Raw materials. In: Hendel O, ed. Technology Brewing & Malting. 6th ed. VLB Berlin; 2019:39–107.

- ↑ Meussdoerffer F, Zarnkow M. Starchy raw materials. In: Esslinger HM, ed. Handbook of Brewing: Processes, Technology, Markets. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.

- ↑ Miedl-Appelbee M. Brewhouse technology. In: Stewart GG, Russell I, Anstruther A, eds. Handbook of Brewing. 3rd ed. CRC Press; 2017.

- ↑ Holbrook CJ. Brewhouse operations. In: Smart C, ed. The Craft Brewing Handbook. Woodhead Publishing; 2019.

- ↑ a b Fox GP. Starch in brewing applications. In: Sjöö M, Nilsson L, eds. Starch in Food. 2nd ed. Woodhead Publishing; 2017:633–659.

- ↑ Ratnayake WS, Jackson DS. Starch Gelatinization. In: Advances in Food and Nutrition Research. Academic Press; 2008;55:221–268.

- ↑ Chmelík J, Krumlová A, Budinská M, et al. Comparison of size characterization of barley starch granules determined by electron and optical microscopy, low angle laser light scattering and gravitational field-flow fractionation. J Inst Brew. 2001;107(1).

- ↑ Szwajgier D. "Dry and wet milling of malt. A preliminary study comparing fermentable sugar, total protein, total phenolics and the ferulic acid content in non-hopped worts." J Inst Brew. 2011;117(4):569–577.

- ↑ Yu W, Zhai H, Xia G, et al. Starch fine molecular structures as a significant controller of the malting, mashing, and fermentation performance during beer production. Trends Food Sci Technol. 2020;105:296–307.

- ↑ Krottenthaler M, Back W, Zarnkow M. Wort production. In: Esslinger HM, ed. Handbook of Brewing: Processes, Technology, Markets. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.

- ↑ Langenaeken NA, De Schepper CF, De Schutter DP, Courtin CM. Different gelatinization characteristics of small and large barley starch granules impact their enzymatic hydrolysis and sugar production during mashing. Food Chem. 2019;295:138–146.

- ↑ Keßler M, Kreisz S, Zarnkow M, Back, W. Do brewers need a starch modification index? Brauwelt International. 2008;1:52–55.

- ↑ Slack PT, Baxter ED, Wainwright T. Inhibition by hordein of starch degradation. J Inst Brew. 1979;85(2):112–114.

- ↑ Cozzolino D, Degner S. An overview on the role of lipids and fatty acids in barley grain and their products during beer brewing. Food Res Int. 2016;81:114–121.

- ↑ Lewis MJ, Young TW. Brewing. Springer; 2001:234.

- ↑ a b c d Kunze W. Wort Production. In: Hendel O, ed. Technology Brewing & Malting. 6th ed. VLB Berlin; 2019:220–221.

- ↑ a b c Krottenthaler M, Back W, Zarnkow M. Wort production. In: Esslinger HM, ed. Handbook of Brewing: Processes, Technology, Markets. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.

- ↑ a b c Fix G. Principles of Brewing Science. 2nd ed. Brewers Publications; 1999.

- ↑ a b c Slack PT, Wainwright T. Amylolysis of large starch granules from barleys in relation to their gelatinisation temperatures. J Inst Brew. 1980;86:74–77.

- ↑ a b c Mousia Z, Balkin RC, Pandiella SS, Webb C. The effect of milling parameters on starch hydrolysis of milled malt in the brewing process. Process Biochem. 2004;39(12):2213–2219.

- ↑ a b c Sacher B, Becker T, Narziss L. Some reflections on mashing – Part 2. Brauwelt International. 2016;6:392-397.

- ↑ MacGregor AW, Bazin SL, Macri LJ, Babb JC. Modelling the contribution of alpha-amylase, beta-amylase and limit dextrinase to starch degradation during mashing. J Cereal Sci. 1999;29(2):161–169.

- ↑ Langenaeken NA, De Schepper CF, De Schutter DP, Courtin CM. Different gelatinization characteristics of small and large barley starch granules impact their enzymatic hydrolysis and sugar production during mashing. Food Chem. 2019;295:138–146.

- ↑ a b Narziss L, Back W, Gastl M, Zarnkow M. Abriss der Bierbrauerei. 8th ed. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2017.

- ↑ Pahl R, Meyer B, Biurrun R. Wort and Wort Quality Parameters. In: Bamforth CW, ed. Brewing Materials and Processes: A Practical Approach to Beer Excellence. Academic Press; 2016.

- ↑ Morrison WR, Tester RF, Gidley MJ. Properties of damaged starch granules. II. Crystallinity, molecular order and gelatinisation of ball-milled starches. J Cereal Sci. 1994;19(3):209–217.

- ↑ Warpala IWS, Pandiella SS. Grist fractionation and starch modification during the milling of malt. Food and Bioproducts Processing. 2000;78(2):85–89.

- ↑ Evans DE, Fox GP. Comparison of diastatic power enzyme release and persistence during modified Institute of Brewing 65°C and Congress programmed mashes. J Am Soc Brew Chem. 2017;75(4):302–311.

- ↑ Evans DE, Li C, Eglinton JK. The properties and genetics of barley malt starch degrading enzymes. In: Zhang G, Li C, eds. Genetics and Improvement of Barley Malt Quality. Springer; 2010:143–189.

- ↑ Evans DE, Collins H, Eglinton J, Wihelmson A. Assessing the impact of the level of diastatic power enzymes and their thermostability on the hydrolysis of starch during wort production to predict malt fermentability. J Am Soc Brew Chem. 2005;63(4):185–198.

- ↑ Howe S. Raw materials. In: Smart C, ed. The Craft Brewing Handbook. Woodhead Publishing; 2019.

- ↑ a b c d e f Meussdoerffer F, Zarnkow M. Starchy raw materials. In: Esslinger HM, ed. Handbook of Brewing: Processes, Technology, Markets. Weinheim, Germany: Wiley-VCH Verlag GmbH & Co. KGaA; 2009.

- ↑ Briggs DE, Boulton CA, Brookes PA, Stevens R. Brewing Science and Practice. Woodhead Publishing Limited and CRC Press LLC; 2004.